Expertise Proven for Advanced Technology: MBR System for Wastewater Treatment Plant in Leading Textile Company of Bangladesh

Executive Summary

A pioneer group in Bangladesh’s clothing business, developed a washing plant, a Flag Ship facility for apparel manufacture and textile processing. The group has been a significant player in the market for more than 35 years and has expertise working with numerous well-known international brands, including LEVI, G-Star, H&M, Lee, Wrangler, American Eagle, Debenhams, JC Penney, Nautica, and others. The washing plant is located at Salna, Gazipur near the Capital, Dhaka. About ten years back, the industry was founded to produce high-end denim and non-denim items using ecological practices and European-quality equipment.

Being the second largest exporting industry in Bangladesh, Textile industry is producing high volume of wastewaters creating threat to our environment. Keeping this in mind, Bangladesh government and international buyers imposed regulations for installation of Effluent Treatment Plant in textile industries. As a part of CSR activities, the owner of washing plant was keen to invest on environmental sustainability including wastewater treatment plant, water reuse and recycling.

Objective

The main goal of end user was to establish a fully biological effluent treatment plant compatible for less space with the future provision of water recycling scheme. Their aim is to use the treated effluent as process water in their washing plant.

Solution

Owing to achieve the aim of sustainable effluent treatment plant (ETP), end user adopted Membrane Bioreactor based ETP system. The professionals of environmental experts were major participants for execution of this state of art project.

This plant has a treatment facility of 3.6 MLD and uses a 3-step design comprising of biological treatment, the MBR for solid-liquid separation, and future provision for reverse osmosis (RO) membrane filtration. The feature of single header membrane allows to consistently filter water with turbidity less than 0.5 NTU.

In comparison to conventional technologies, MBR ultrafiltration membranes entirely retain suspended solids in the bioreactor, providing effluent of greater quality while being unaffected by biological disturbances. For optimum performance, the system incorporates a reinforced hollow fibre membrane that is nearly indestructible and has tightly spaced pores. The accumulation of hair and fibrous material that can cause blockage is eliminated by the innovative single header design and central aeration system.

Design of compact bioreactor tank and automatic pretreatment unit with fine screening are prime prerequisite for successful MBR system operation in effluent treatment plant. Keeping the maximum design of MLSS at 8000 mg/L, the compact bioreactor was designed and continuously the slurry type wastewater is fed to MBR tank for filtration.

The full plant was designed and commissioned based on SCADA automation system for making MBR system functional and user friendly to customer. The process design, mechanical, electrical and civil design including programming software was completely planned and designed by local engineers who are professional in this field. The members of environmental experts rendered active role of the engineer’s team for this successful project.

Accomplishments

The end user of the washing plant had a biochemical ETP of 50 m3/hr. before establishing this MBR ETP. The operation cost of that ETP became a headache for the end user due to high chemical consumption and frequent desludging from tank. The frequent maintenance of biochemical treatment system was also a nuisance for them.

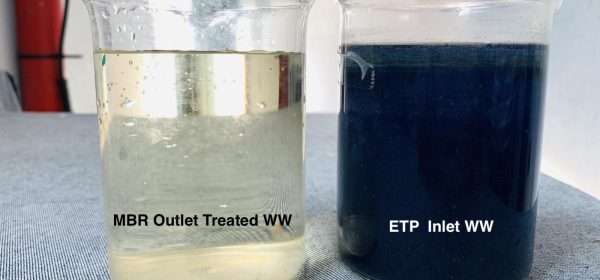

After commissioning of MBR ETP, high chemical consumption and other maintenance cost has been reduced making the plant user friendly with less manpower for operation. The treated wastewater quality is consistently meeting the foundational limit of ZDHC; BOD5 < 10 mg/L, COD < 80 mg/L, TSS < 5 mg/L. Therefore, the plant’s owner will be able to feed this treated water directly to reverse osmosis for recycling to their washing plant. Currently, the MBR outlet water is so fine that end user is using this water in gardening, toilet flushing and in washing process for first wash water

Key Success Factors

This washing plant is continuously receiving appreciation from different buyers for excellent quality of treated wastewater from ETP. The owner of this plant is immensely satisfied with overall ETP performance including single header MBR filtration quality. The native professionals involved in design and execution of this MBR ETP are always ready to provide their support to the end user. Therefore, the end user is getting prompt response from the professionals regarding regular after sales service, technical supervision and consultancy for smooth and trouble-free operation of this advanced technology ETP system.

- By admin

- No Comments